- >

- Workflow Platform>

- Manufacturing 4.0: Unlocking Productivity Gains With AI-Powered Workflow Automation

Manufacturing 4.0: Unlocking Productivity Gains With AI-Powered Workflow Automation

The factory floor today looks nothing like it did five years ago. Sure, the physical equipment might be similar, but the intelligence behind how it operates has fundamentally changed. Welcome to Manufacturing 4.0, where AI-powered workflow automation is transforming production from a reactive, manual process into a self-optimizing, intelligent system.

The impact is tangible. The AI in manufacturing market, valued at $23.40 billion in 2024, is predicted to reach $155.04 billion by 2030, expanding at a compound annual growth rate of 35.3 percent. But the real story isn't in the market size. It's in what manufacturers are actually achieving with these systems.

The human error problem

Let's start with an uncomfortable truth: human error in manufacturing is expensive. A misread gauge. A forgotten quality check. A delayed maintenance schedule. These small mistakes compound into serious problems: production delays, quality issues, and safety incidents.

Over 90 percent of workers say automation increases their productivity, and manufacturers are seeing why. AI workflow automation doesn't just reduce errors. It fundamentally changes how work gets done, shifting humans from repetitive, error-prone tasks to higher-value problem-solving.

Where smart factory AI workflows deliver ROI

Predictive maintenance: the game changer

Traditional maintenance follows a simple playbook: fix it when it breaks, or maintain it on a fixed schedule regardless of actual condition. Both approaches leave money on the table.

AI-powered predictive maintenance changes the equation entirely. By analyzing sensor data, vibration patterns, temperature fluctuations, and historical performance, these systems predict equipment failures before they happen.

The numbers are striking. Predictive maintenance can save up to 40 percent of repair costs. More importantly, it prevents the catastrophic failures that bring entire production lines to a halt.

One automotive manufacturer we studied reduced unplanned downtime by 35 percent in the first year after implementing AI-driven predictive maintenance workflows. Their maintenance teams shifted from firefighting to strategic planning, and production reliability improved across the board.

Supply chain coordination that actually works

Supply chain visibility has been a promise for decades. AI workflow automation is finally delivering on it.

According to recent data, 92 percent of supply chain executives admit they make gut decisions at times because their reports don't provide predictive guidance. AI changes that dynamic completely.

Modern AI systems track components across the entire supply chain, automatically flagging potential delays, suggesting alternative suppliers, and rebalancing production schedules to accommodate disruptions. The system learns from every deviation, continuously improving its predictions and recommendations.

The result? AI solutions contribute to manufacturers' core production processes across the board: 24 percent to assembly and quality testing, 23 percent to product development and engineering, and 20 percent each to procurement, order management, and logistics.

Shop-floor visibility in real time

Here's where Manufacturing 4.0 gets interesting. Traditional manufacturing operated on delayed information. You'd discover quality issues hours or days after they occurred. By then, you've already produced hundreds or thousands of defective units.

AI-powered workflow automation provides real-time visibility across the entire shop floor. Computer vision systems inspect every part coming off the line. Sensor networks track production flow and identify bottlenecks as they form. Analytics platforms surface patterns that humans would never spot.

Over 50 percent of manufacturers are expected to integrate AI-powered quality control and predictive maintenance systems by 2025. The competitive advantage goes to those who can see problems before they become expensive.

60 percent of industrialists use AI for quality monitoring, and these systems are detecting 200 percent more supply chain disruptions than traditional methods. That's not just better visibility. That's a fundamental change in how manufacturing operations are managed.

The productivity multiplier effect

Let's talk about what productivity actually means in a Manufacturing 4.0 context. It's not just about making more widgets per hour.

Operators using AI in manufacturing report a 10 percent to 15 percent boost in production processes and a 4 percent to 5 percent increase in EBITA. But the more interesting metric is capacity utilization. When you reduce downtime, minimize quality issues, and optimize workflows, you're essentially creating capacity without adding equipment or headcount.

AI-driven automation could reduce operational costs by 20-30 percent while increasing production output by 10-15 percent. The compound effect becomes obvious: you're producing more, with higher quality, at lower cost.

One electronics manufacturer calculated that AI workflow automation added the equivalent of 15 percent additional production capacity without any capital investment in new equipment. They simply optimized how existing assets were used.

Smart factory: more than a buzzword

The term "smart factory" gets thrown around often, but what does it actually mean?

A smart factory isn't just a facility with a lot of sensors and screens. It's a manufacturing environment where workflows adapt automatically to changing conditions. Where quality issues trigger immediate responses. Where production schedules optimize themselves based on real-time demand signals.

52 percent of manufacturers have adopted AI tools, and they're building these intelligent environments step by step. They start with specific workflows, prove value, then expand to adjacent processes.

The key is integration. AI workflow automation delivers maximum value when systems talk to each other: when quality control feeds back to production planning, when predictive maintenance informs scheduling, when supply chain data automatically adjusts inventory levels.

The ROI reality check

Let's be direct about returns. Companies investing in automation see an average 22 percent reduction in operating costs, with robotic process automation delivering 30 percent to 200 percent ROI in the first year.

But ROI isn't just about cost reduction. It's about:

Improved Quality: Fewer defects mean less rework, fewer returns, and better customer satisfaction.

Increased Flexibility: AI-powered workflows adapt faster to product changes and demand fluctuations.

Better Resource Utilization: When machines and people work at optimal efficiency, you get more from existing assets.

Reduced Risk: Predictive systems catch problems before they become expensive failures.

Rockwell Automation, for example, developed a suite of AI-powered tools that analyze sensor data to predict equipment failures and recommend preventative maintenance. They've integrated AI-powered robots to automate complex tasks and create more efficient production lines. The result? Manufacturers using their systems reduce downtime, minimize waste, and optimize production schedules, translating to significant cost savings and increased output.

The implementation challenge

Here's the hard truth: about 70 percent of digital transformation and automation projects fail to meet objectives. The difference between success and failure isn't technology. It's approach.

Successful manufacturers follow a specific pattern:

-

Start Small: Pick one high-value workflow to automate first. Prove the concept before expanding.

-

Build on Existing Infrastructure: You don't need to rip and replace everything. Modern AI systems integrate with existing equipment and software.

-

Focus on Measurable Outcomes: Define clear metrics before implementation. Track them religiously.

-

Invest in Skills: 44 percent of CFOs note a workflow automation skills gap among their teams. Address this early with training and strategic hires.

-

Iterate and Improve: The first implementation won't be perfect. Build in continuous improvement cycles.

Looking forward: the competitive imperative

Workers using AI tools boost their performance by up to 40 percent compared to those without. In manufacturing, that productivity advantage compounds across every shift, every line, every facility.

The manufacturers winning in 2025 aren't necessarily the biggest or best-funded. They're the ones who've systematically automated their core workflows, freeing their teams to focus on innovation and continuous improvement.

Manufacturing 4.0 isn't about replacing skilled workers with robots. It's about augmenting human capability with intelligent systems. When you automate routine monitoring and decision-making, you free people to do what they do best: solve complex problems, improve processes, and drive innovation.

The global industrial automation and control systems market is projected to reach $252.7 billion in 2025, up from $206.3 billion in 2024. That growth reflects a fundamental shift in how manufacturing operates.

The question isn't whether to adopt AI workflow automation. With 35 percent of manufacturing firms already utilizing AI technologies, and adoption accelerating rapidly, the question is how quickly you can implement it to maintain competitive advantage.

The productivity gains are real. The ROI is measurable. The competitive pressure is mounting. The smart factory revolution is here, and it's powered by AI workflow automation that makes every process more efficient, every decision more informed, and every operation more productive.

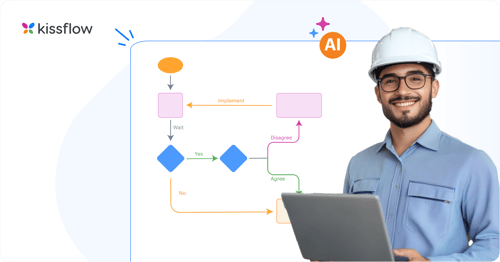

Building your smart factory with the right platform

Kissflow brings AI-powered workflow automation to manufacturing operations without the complexity of traditional enterprise systems. Whether you're automating quality control processes, streamlining supply chain coordination, or optimizing maintenance workflows, Kissflow's intuitive platform makes it easy to design, deploy, and refine automated workflows. With real-time visibility across your shop floor operations and seamless integration with existing manufacturing systems, Kissflow helps you achieve Manufacturing 4.0 goals faster. Our manufacturing customers report reduced downtime, improved quality metrics, and significant cost savings within the first quarter of implementation.

Ready to unlock smart factory productivity gains? See how Kissflow can transform your manufacturing workflows.

Related Topics:

- Boosting Operational ROI in Oil & Gas with AI Workflow Automation

- Smarter Campuses, Smarter Operations: AI Workflow Automation in Education

- AI Workflow Automation in Finance: Accuracy, Compliance, and Profitability Combined

Related Articles