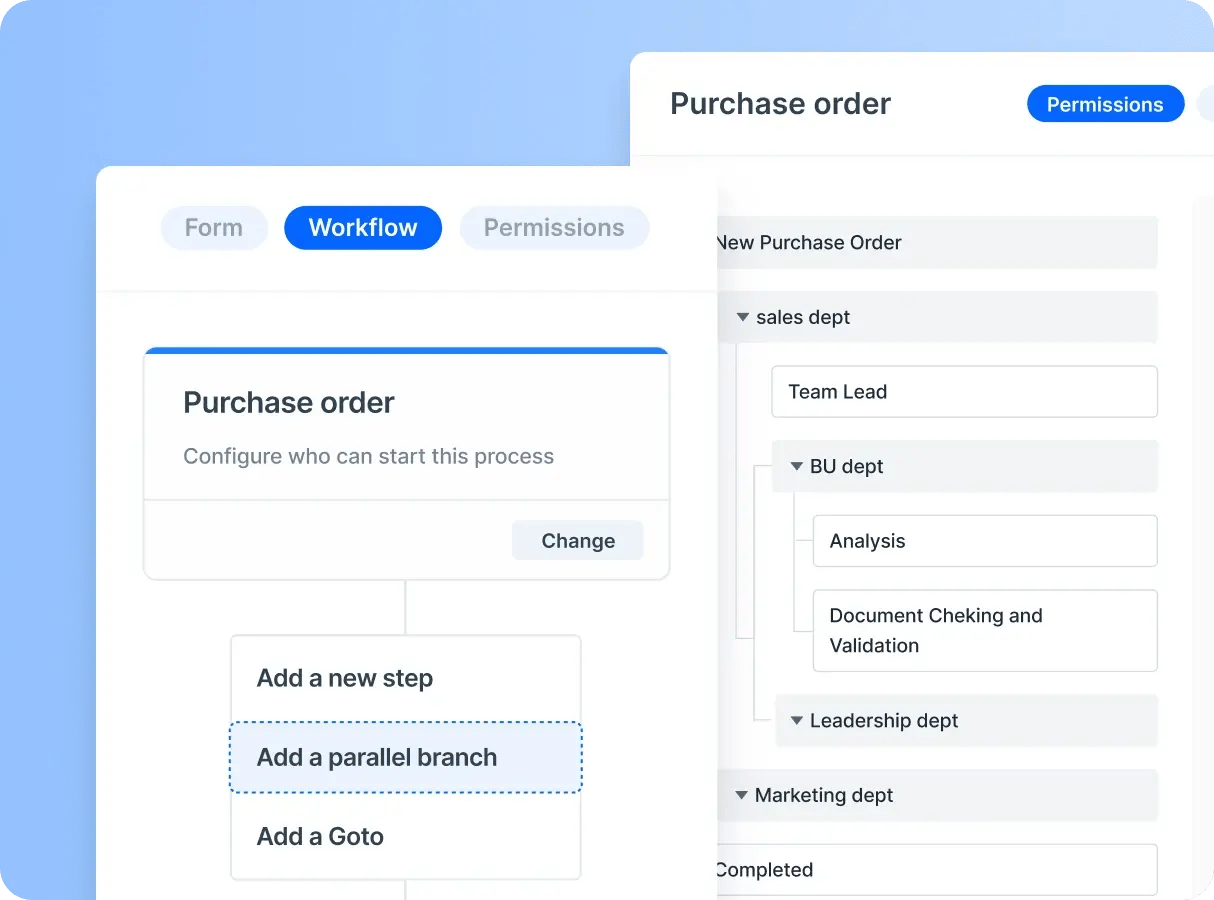

Process automation and standardization

-

Eliminate manual, error-prone workflows

-

Standardize best practices across all sites

-

Reduce administrative burden on field teams

-May-15-2025-11-55-57-8886-AM.png)

-May-15-2025-11-55-57-9426-AM.png)