The manufacturing industry is an engine of economic growth. According to research, American manufacturers contribute more than $2.35 trillion to the US economy. An additional $2.79 is added to the economy for every dollar spent on manufacturing.

Efficiency and sustainability are critical for manufacturing companies as they produce large volumes of goods with a high turnover. In the past, manufacturing companies digitized only their core functions with Enterprise Resource Planning (ERP) and Material Requirements Planning (MRP) software. Industry 4.0 has changed the landscape, and manufacturers are now looking for ways to optimize their factories and supply chains while also improving employee safety.

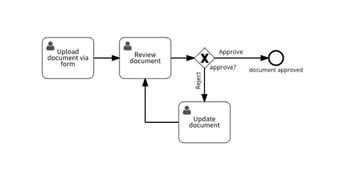

BPM in manufacturing can digitize manual workflows, which can, in turn, lead to improved operational transparency, higher product quality, and compliance with custom-defined operating procedures. Let's take a look at how streamlining business process management can vastly improve output:

Why the need for process efficiency in the manufacturing industry?

Process efficiency is important in manufacturing because it ensures assembly lines keep producing as many goods as possible all the while increasing productivity and potential profits. Manufacturing efficiency also ensures products are produced at the lowest possible price.

BPM in the manufacturing industry cuts costs, improves output, and reduces environmental impact. These general benefits result in additional gains like increased sales, better products, and an improved company image.

Boosting revenue and growth in today’s competitive manufacturing environment takes more than incremental improvement and downsizing. Forward-thinking companies use Business Process Management (BPM) tools to optimize operational performance in primary processes (such as production and supply chain) and support processes (such as recruiting and health and safety).

A BPM platform enables companies to eliminate organizational silos effectively by providing better agility, visibility, and, most importantly, better control over processes.

How to streamline business processes in manufacturing

Go paperless

One great way to streamline manufacturing processes while saving the planet is to go paperless. Paperwork wastes money, time, and space. Employees spend hours sifting through countless papers to find a single document. If you store all your files digitally, you can process a larger volume of work.

Use technology to improve communications between teams

When employees use a single BPM platform, work moves faster. The production and engineering teams can work together to quickly improve products and deliver them to the market. Research and sales teams can easily track consumer behavior to understand which items are more popular than the others.

In make-to-order manufacturing, time is critical because as soon as the sales team gets an order, it sets a delivery date for the customer. There’s constant communication between different teams to ensure goods are ready by the delivery date. BPM can expedite delivery dates by streamlining cross-team collaboration and communication.

Improve quality control

Quality control is critical in manufacturing because a company wastes time and resources if products don’t meet industry requirements. A BPM platform for quality control ensures products are free from defects, processes are efficient, and goods meet quality standards before they leave the manufacturing facility. The platform can alert quality control officers about inspections, testing, and reviews so they can identify and correct product defects in advance.

5 examples of how streamlining BPM in manufacturing can improve efficiency and overall throughput

Improved production

Production is a core manufacturing process. Without it, there are no finished goods and nothing to sell to customers. A BPM manufacturing platform can increase the speed, flexibility, and efficiency of production processes. It helps manufacturers reduce costs and improve product quality.

By automating processes, the system can optimize schedules to minimize defects and inefficiencies, resulting in higher-quality products. Business process management in manufacturing expedites production, ensuring more products are made in less time—with consistent results.

Better supply chain management

Supply chain management encompasses all manufacturing processes, from sourcing raw materials to delivering goods to customers. A BPM system can help manufacturers plan, procure, manufacture, transport, and store their goods well.

By streamlining logistics, the system ensures products are delivered to customers promptly while minimizing costs. It gives manufacturers visibility into their entire supply chain and allows them to effectively manage all the different components.

Strategic marketing

Marketing is a lengthy process that involves lead generation, lead nurturing, and sales. Every day, sales and marketing professionals must conduct market research, promote products, and sell them well to ensure customer satisfaction.

A business process management platform streamlines marketing, helping marketers generate more revenue for their companies. Marketers have a good understanding of their target audience, their needs, and their buying behavior. They use this information to develop effective marketing strategies.

In the digital age, managing a manufacturing business means not only crafting efficient real-world workflows but also leveraging online data for strategic advantages. Utilizing proxies for web scraping allows businesses to gather critical market intelligence discreetly and efficiently, ensuring marketing strategies are backed by the most current data. This approach transforms how companies understand consumer behavior, competitor activities, and market trends, contributing significantly to well-informed decision-making and effective campaign planning.

Efficient accounting and finance

Accurate accounting helps manufacturers set good pricing policies. When you know your costs, you can easily determine sales prices. A good BPM system helps manufacturers determine costs so they sell goods at a fair price while maximizing their profit.

BPM can ensure that company finances are healthy and meet production needs.

Better manufacturing management

Good management greatly lowers manufacturing costs. Managers can use a BPM system to optimize workflows, decrease product waste, reduce the input involved, and maximize output — all which can improve profit margins. Managers can also use the system to delegate tasks to workers, streamline production, monitor the quality of goods, and ensure efficient delivery.

The right BPM system can streamline manufacturing processes and offer other benefits

Companies are always striving for higher manufacturing efficiencies to compensate for rising business costs. This can’t be achieved without technology. A good BPM tool can help manufacturers analyze and measure the resources they use, how much they scrape, and how much time is spent on manufacturing.

They can operate with less waste, better efficiency, and fewer workers, allowing them to achieve long-term savings. Automation expedites production, so products are made more quickly and efficiently.

The Kissflow BPM platform makes streamlined processes a reality

Modern manufacturing companies face many challenges — accelerated change, high development costs, decreased customer loyalty, and more. They must modify existing workflows and develop new solutions quickly to keep up with marketplace changes. Kissflow’s BPM platform provides core BPM functions and allows operational staff to design, modify, and deploy solutions whenever needed.

The business process management system allows for single-process transformation, system integration, and end-to-end automation and transformation. Continuous operational improvement can quickly become a reality.

Sign up for a free trial today and start enjoying the many benefits of business process management in manufacturing.