Digitize HSE Operations Without Disrupting Safety Protocols

Designed for HSE teams who demand safety, speed, and organization

.webp?width=1090&height=928&name=first_fold%20(2).webp)

Trusted by global oil and gas leaders

Proven HSE Excellence

67% faster

Permit approvals

89% more

HSE issues closed on time

Zero

Safety audit issues

HSE Oil and Gas teams struggle with

Incident reports lost in email chains

Permit-to-work approvals stuck in someone's inbox

Contractor safety records you can't find

Safety observations buried in spreadsheets

QHSE processes scattered across disconnected systems

Risk assessments filed away, never referenced

The digital backbone connecting all your HSE workflows

Works in the field

Mobile-ready for tablets, works in hazardous areas

Connects to your systems

Links with your maintenance software (SAP, Maximo)

Audit-ready always

Digital signatures and document control built-in

OSHA logic built-in

Automatic classification saves time and reduces errors

CAPA workflows automated

Corrective actions get tracked, not forgotten

Higher close-out rates

No more incidents sitting open for months

Ready-to-deploy HSE applications

Incident and near-miss tracker

Untracked incidents become serious accidents. Document thoroughly to prevent escalation.

Read more

Job Safety Analysis (JSA)

With our intuitive JSA app, you can handle hazard identification, risk assessment, control planning, and approvals all in one place. Designed for industrial teams, this Job Safety Analysis app takes the hassle out of job hazard assessments, making it the ideal safety solution for high-risk tasks and compliance-driven organizations.

Read more

Emergency Drill Management App

With our intuitive Emergency Drill Management App, you can plan, schedule, execute, and audit all types of emergency preparedness drills—fire, chemical spill, evacuation, and more—in one centralized place.

Read more

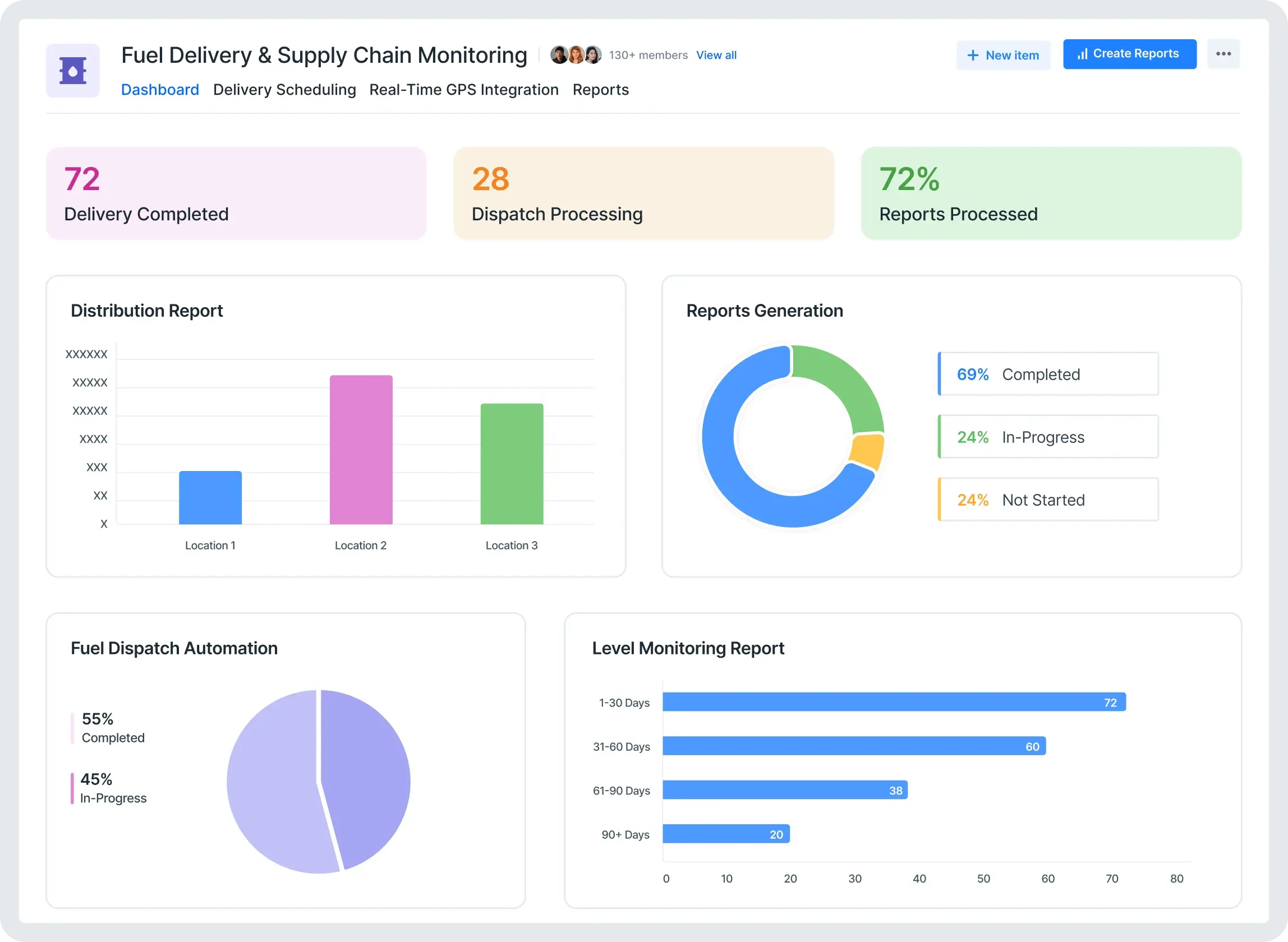

Fuel Delivery & Supply Chain Monitoring

With our intuitive Fuel Delivery & Supply Chain Monitoring system, you can handle dispatches, delivery status, escalations, and driver compliance all in one place. Designed to be simple and efficient, this fuel delivery app takes the hassle out of tracking fuel movement, making it the ideal logistics software for oil & gas retail and distribution teams.

Read more

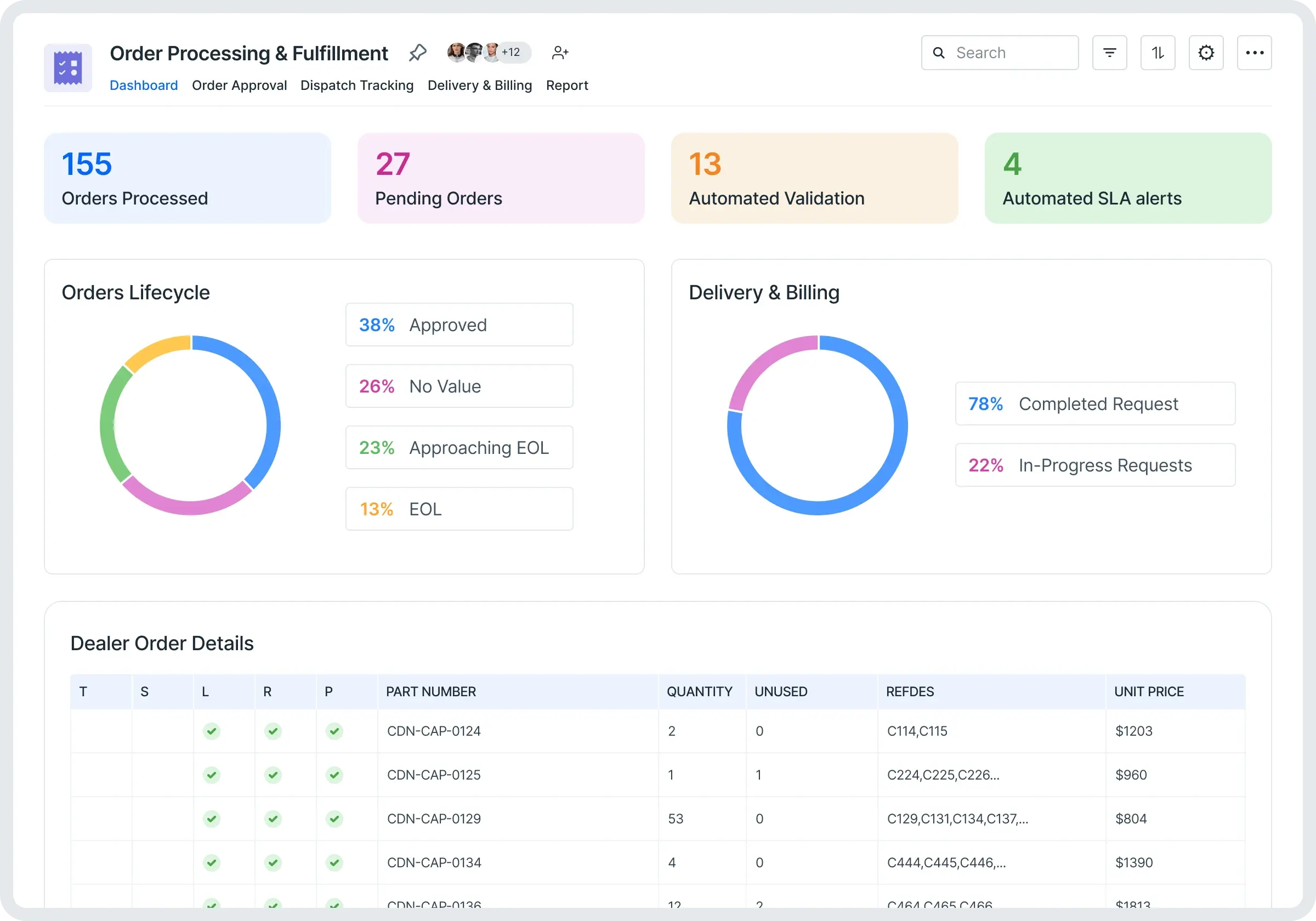

Order Processing & Fulfillment

With our intuitive Order Processing & Fulfillment system, you can handle dealer order placement, approvals, dispatches, and billing all in one place. Designed to be simple and efficient, this app eliminates email trails, phone follow-ups, and manual reconciliation, making it the ideal order tracking software for fuel, lubricant, and retail distribution networks.

Read more

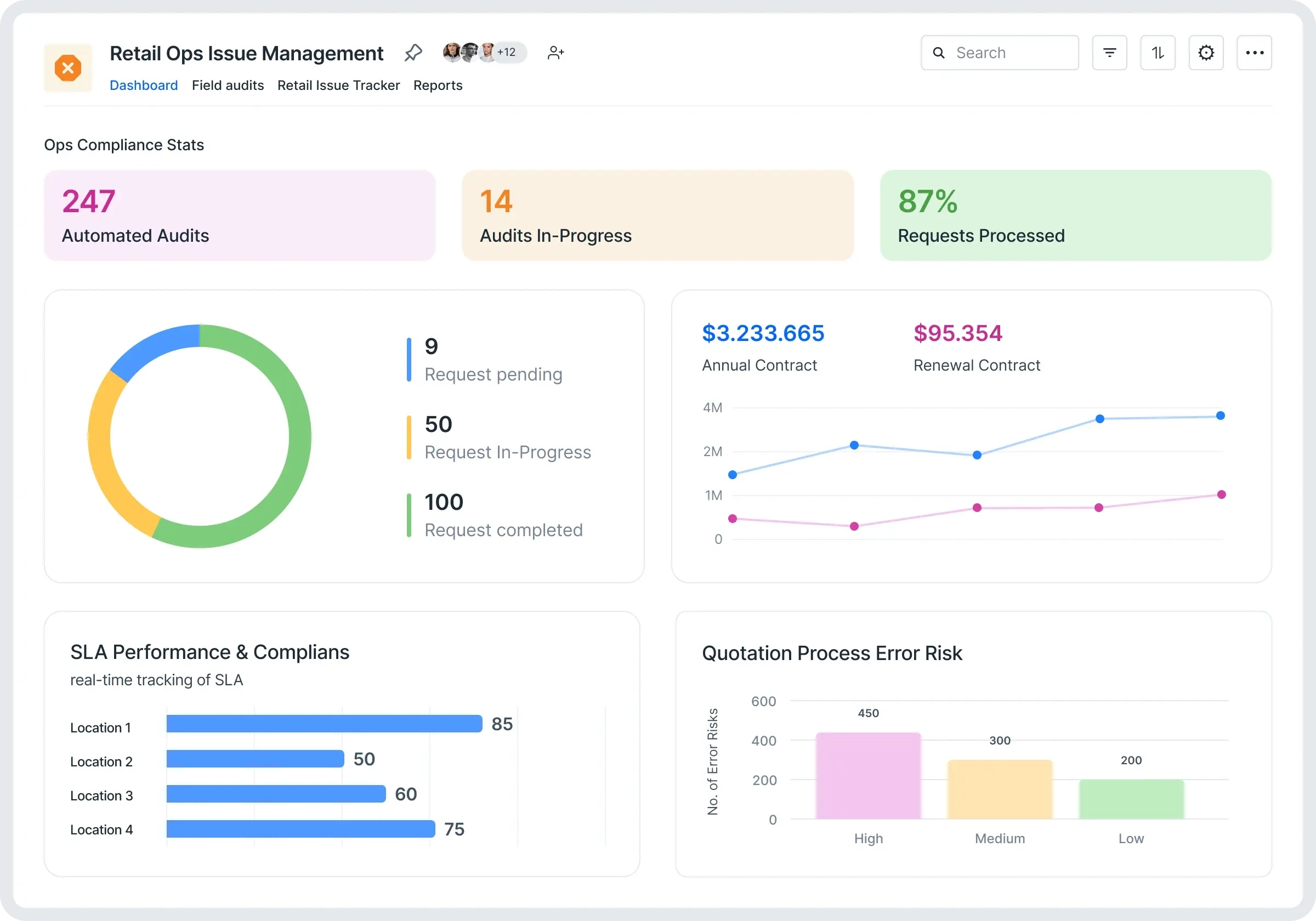

Retail Ops Issue Management

With our intuitive Retail Ops Issue Management system, you can handle field disruptions, branding material requisitions, and resolution tracking all in one place. Designed to be simple and efficient, this app takes the hassle out of field support, making it the ideal operations and issue tracking software for multi-site retail networks.

Read more

All your apps on a single platform

Explore The App Store >- Budget Approval

- Expense Management

- Payables and Receivables

- Treasury Requests

- Capital Expenditure

Travel Reimbursement Admin Service Requests Record keeping Maintenance Scheduling IT Service Requests

- Leave Management

- Performance Management

- Employee Management

- Department Transfers

- HR Benefits Requests

Proven success across oil and gas

Major oil and gas companies worldwide have transformed their operations with Kissflow

This is so easy, even my mom could do this. It was extremely intuitive and straightforward. The watermark was, 'I don't need to call IT to do this. I can do it myself.

Renee Villarreal

Senior IT Manager

Industry

Energy

HeadQuaters

USA

Key Highlights

450+

Process

10x

ROI

10,000+

Users

Watch Puma Energy's

leap forward into digital transformation

“[With Kissflow,] you are able to utilize the business language, which is actually English or Spanish to code. You don't need to learn how to do this on .net or C++ anymore.”

Tanay Tiwary

Global Head - Digitalization & Business Improvement

Transform safety operations without compromising

Frequently Asked Questions

Relying on spreadsheets and email for critical HSE workflows leads to risks such as lost data, lack of audit trails, and slow approvals. Auditors struggle to verify actions taken. Untracked handoffs and missing documentation can put compliance and operational safety at risk. Your name and accountability are on the line, not the tools you use.

• Untracked or hidden processes open the door to regulatory, operational, business, and personal risks.

• Regulators cannot verify that workflows have been followed.

• Critical steps, such as permit-to-work approvals, get lost or delayed.

• Incident investigations and corrective actions may be missed.

• Maintenance deferrals and engineering changes lack a clear record.

Kissflow offers pre-built workflows for HSE incident tracking. Features include OSHA-based logic, automated incident classification, corrective and preventive action (CAPA) workflows, and built-in audit trails. This leads to faster closure rates, higher compliance, and no audit gaps.

Yes. The platform supports permit management with isolation verification, hazard analysis, and approval workflows designed for industrial environments. Everything is tracked, timestamped, and auditable.

Kissflow keeps all workflows, approvals, and changes fully auditable. Built-in document control and e-signatures make it easy to demonstrate compliance during audits, reducing the risk of fines and findings.

No. Deployment is phased, starting with security and architecture review, piloting a non-critical workflow, and gradually expanding based on user readiness. There is no big-bang switch-over or operational disruption.

Yes. Kissflow is integration-ready. It connects with major systems used in oil and gas, such as SAP, for unified operations and data consistency. With API keys, you can connect with any existing systems.

The platform manages contractor onboarding, job safety analysis, access permissions, and third-party risk in one place. This keeps control over who is on site and what access they have.

Most organizations start seeing measurable improvements—such as faster approvals, reduced audit findings, and time savings—within the first few months after deployment.