Cut Turnaround Time with Automated Contractor Workflows

Streamline turnaround coordination, eliminate contractor delays, and compress shutdown windows—your uptime depends on it

Trusted by global oil and gas leaders

Trying to solve any of these downstream challenges?

Scattered turnaround work packages

Paper permits delay contractors

Lost shift handover information

Weeks-long MOC email approvals

Manual quarterly compliance compilation

Lost paper audit findings

Digitize critical downstream operations

Automate approval routing, standardize data capture, and centralize documentation from refinery to retail—without disrupting 24/7 operations

Refining Operations

Streamline shift handovers, permit-to-work coordination, MOC approvals, and daily operations reporting with complete audit trails

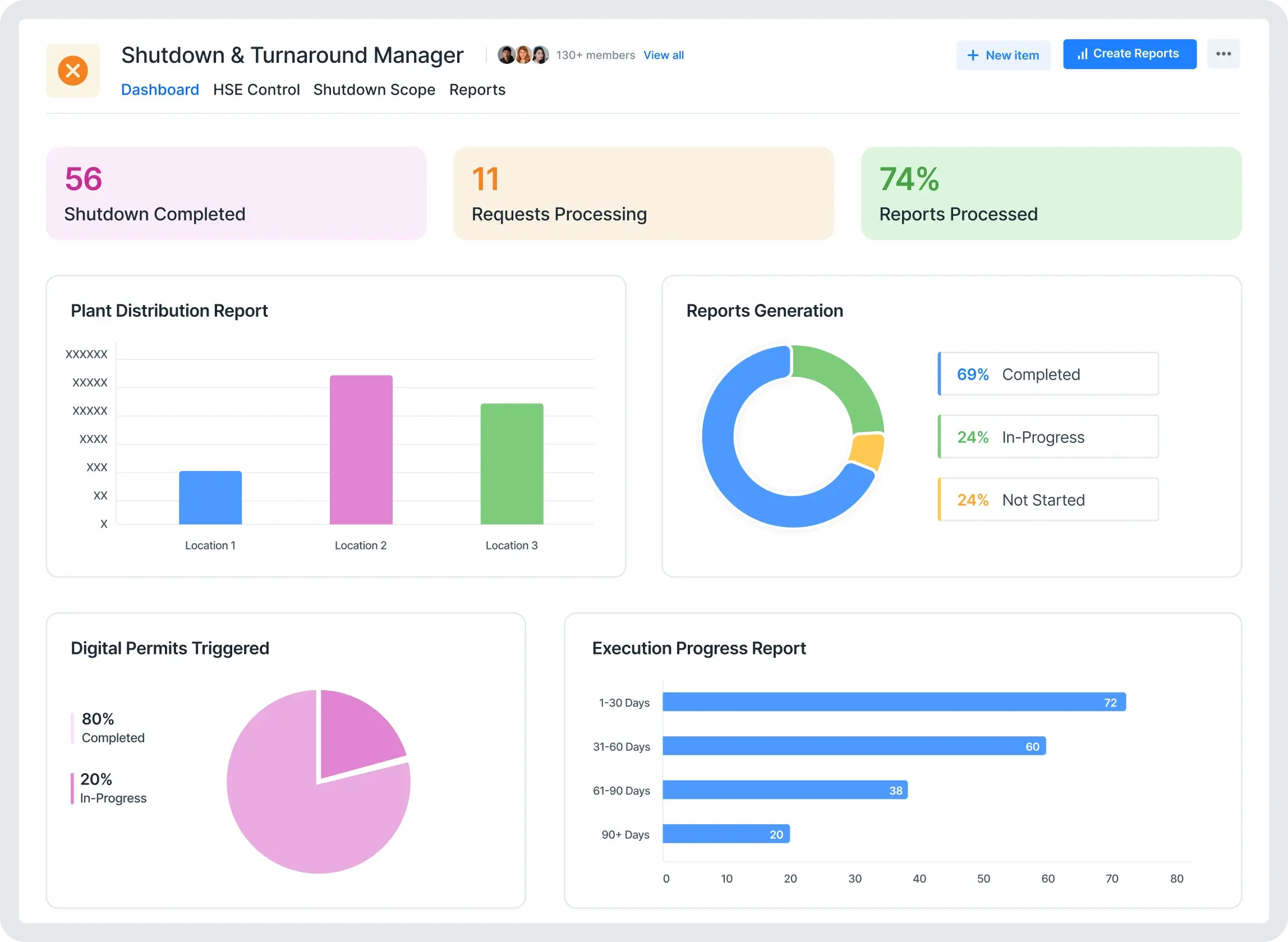

Turnaround & Maintenance

Coordinate turnaround work packages, contractor documentation, deficiency tracking, and QA/QC inspection holds with real-time visibility

HSE & Compliance

Standardize safety inspections, incident reporting, environmental monitoring, and PSM documentation with photo evidence and instant escalation

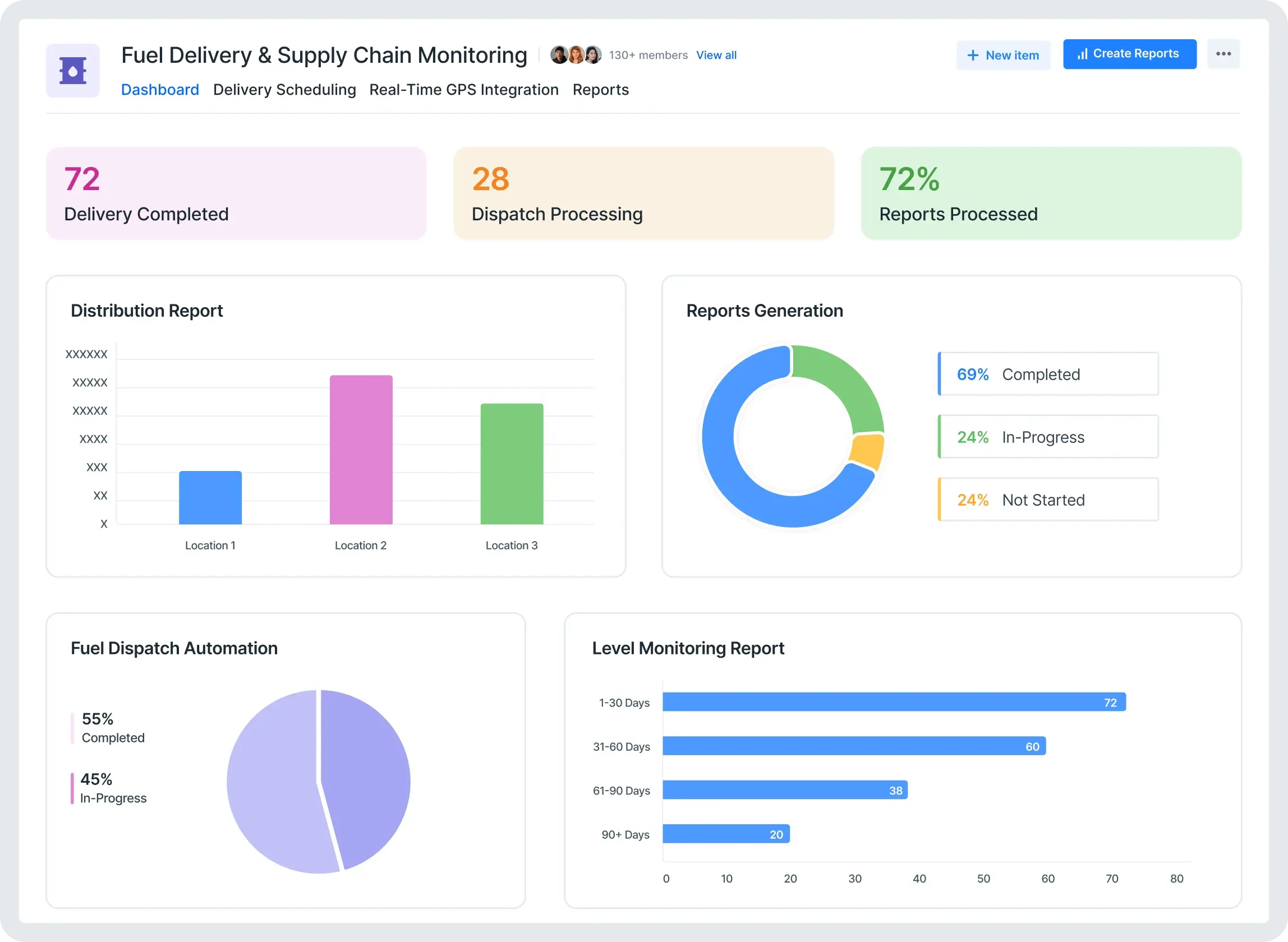

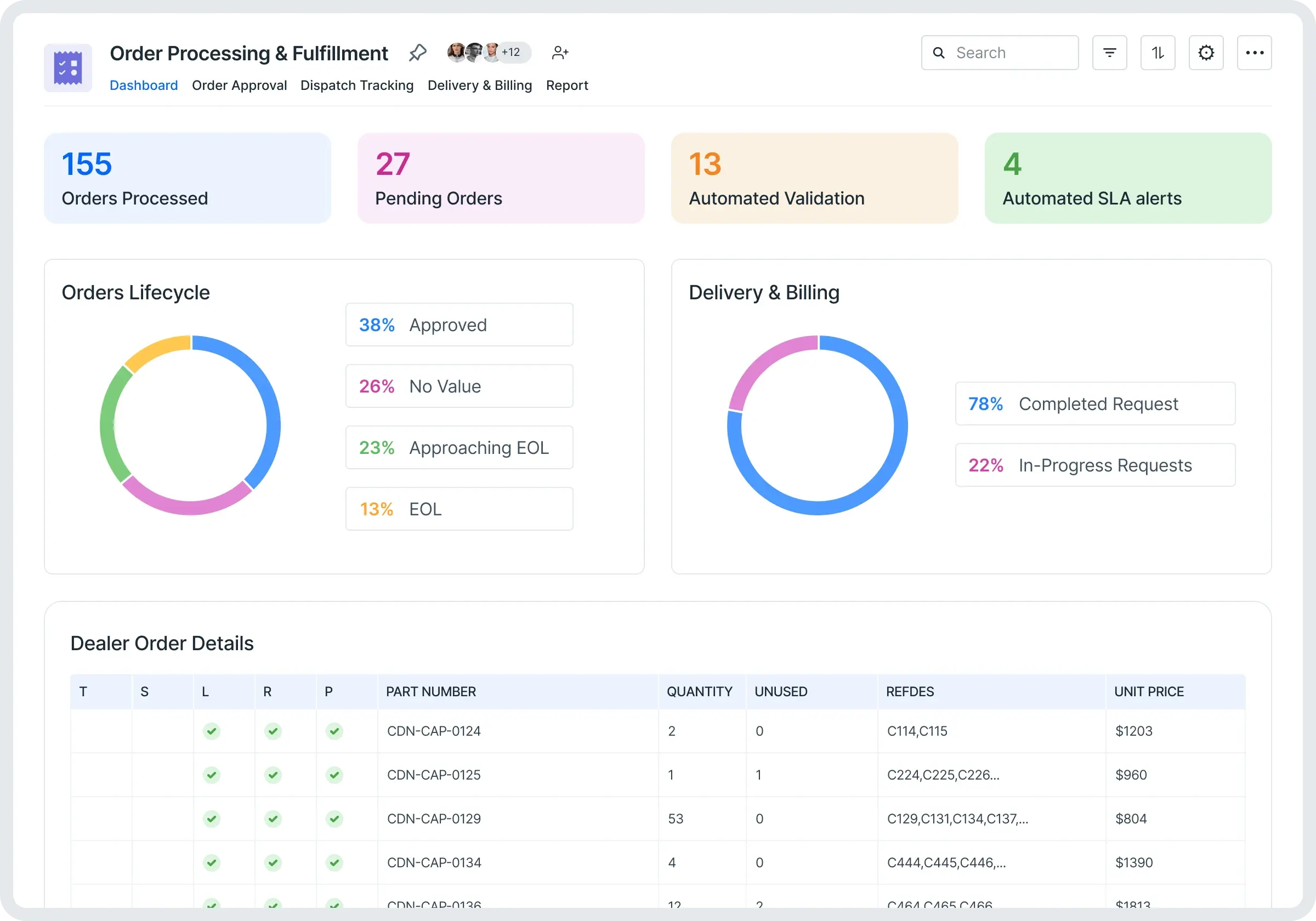

Retail & distribution

Manage site audits, dealer communications, fuel quality tracking, and inventory variance reporting across distributed networks

Workflow automation that speaks your industry language

Drag-and-drop workflow builder

Build shift handover forms, permit requests, and inspection checklists your operations team can modify—without waiting on IT or vendors

Smart approval routing

Automatically route MOCs, capital requests, and contractor qualifications to the right stakeholders based on complexity, cost, and risk level

Mobile-first field operations

Inspectors, technicians, and retail auditors capture data, photos, and compliance evidence on mobile devices—even offline—and sync when connected

Integration with existing systems

Connect to your ERP, CMMS, DCS historian, and document management systems via APIs—Kissflow coordinates workflows across your technology stack

Complete audit trails

Every approval, inspection, and safety observation is timestamped and logged—giving you PSM and EPA-compliant documentation without manual compilation

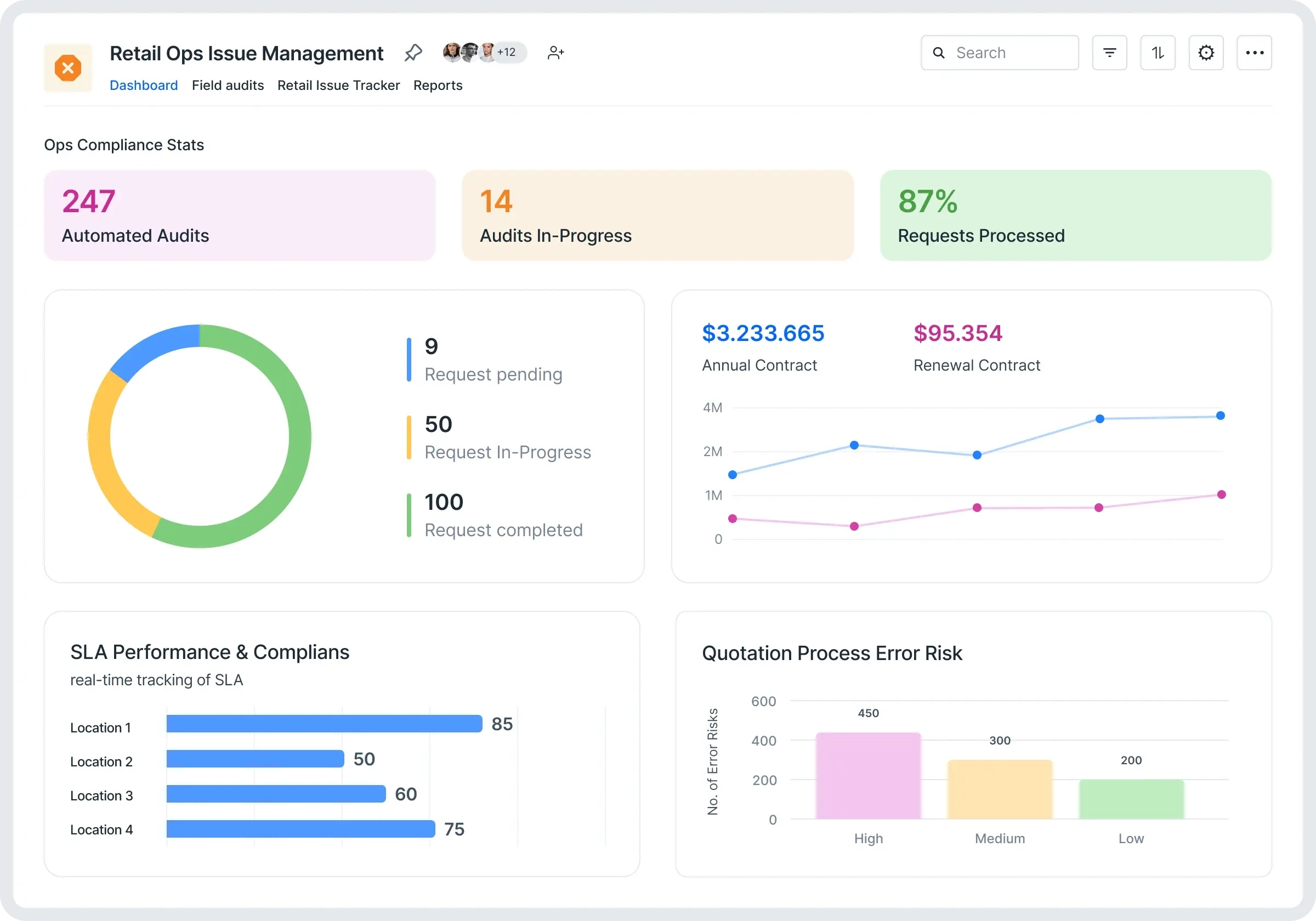

Centralized visibility dashboards

Monitor pending MOCs, open permits, turnaround progress, and retail compliance metrics—but focused on actionable operational data, not vanity metrics

Ready-to-deploy downstream applications

Shift Handover & Operations Log

Digitize shift turnover with production status, equipment issues, safety observations, and action items—searchable history instead of paper logbooks

Read more

Permit-to-Work Coordination

Manage hot work, confined space, line break, and vessel entry permits with automated routing, gas test requirements, and clearance verification

Read more

Management of Change (MOC) System

Route equipment, procedure, and personnel changes through technical review, safety assessment, and stakeholder approval with complete documentation

Read more

Turnaround Work Package Tracker

Coordinate contractor work scopes, track completion status, manage inspection holds, and document deficiencies with photo evidence

Read more

Contractor Qualification Management

Collect safety training records, insurance certificates, and compliance documentation with automated expiration alerts and renewal tracking

Read more

HSE Incident & Near-Miss Reporting

Capture safety observations and incidents on mobile devices, route for investigation, document root cause, and track corrective actions to closure

Read more

All your apps on a single platform

Explore The App Store >- Budget Approval

- Expense Management

- Payables and Receivables

- Treasury Requests

- Capital Expenditure

Travel Reimbursement Admin Service Requests Record keeping Maintenance Scheduling IT Service Requests

- Leave Management

- Performance Management

- Employee Management

- Department Transfers

- HR Benefits Requests

Proven success across oil and gas

Major oil and gas companies worldwide have transformed their operations with Kissflow

This is so easy, even my mom could do this. It was extremely intuitive and straightforward. The watermark was, 'I don't need to call IT to do this. I can do it myself.

Renee Villarreal

Senior IT Manager

Industry

Energy

HeadQuaters

USA

Key Highlights

450+

Process

10x

ROI

10,000+

Users

Watch Puma Energy's

leap forward into digital transformation

“[With Kissflow,] you are able to utilize the business language, which is actually English or Spanish to code. You don't need to learn how to do this on .net or C++ anymore.”

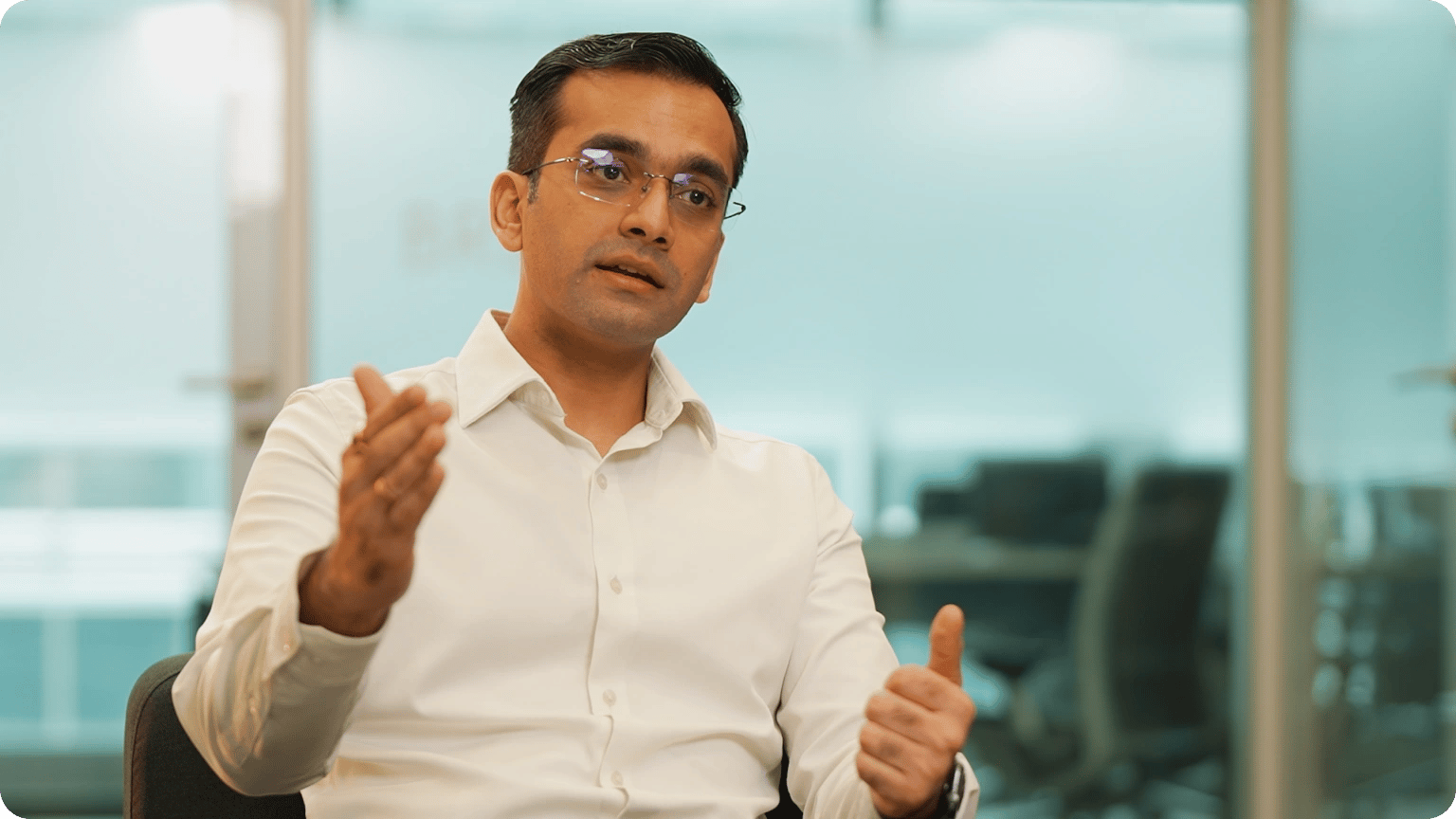

Tanay Tiwary

Global Head - Digitalization & Business Improvement

See Kissflow in action for your downstream operations

Frequently Asked Questions

Kissflow can integrate with DCS historians and data systems for read-only data visualization in dashboards and forms. However, Kissflow does not send control commands to DCS or safety-instrumented systems—it's a business process layer separate from control systems. For example, you might display unit production rates from your historian in a shift handover form, but the actual process control remains in your DCS. Integration scope depends on your historian's API availability and your IT/OT security architecture.

If you have specialized turnaround software (like Prometheus, Meridium APM, or custom systems), Kissflow typically handles the human coordination workflows around it—contractor documentation, permit requests, inspection sign-offs, and deficiency tracking. Detailed critical path scheduling, resource leveling, and cost tracking are typically maintained in your specialized TA software. Kissflow can integrate via APIs to provide visibility and coordinate approvals across systems.

Kissflow provides enterprise-grade security including role-based access controls, data encryption, and audit logging. For critical infrastructure, your cybersecurity team should review the architecture. Kissflow operates as a business process layer separate from safety-critical control systems. Critical question: What's your fallback if the workflow system is unavailable? Manual procedures must always exist for safety-critical operations like emergency response and permit-to-work.

Yes. Every refinery has unique MOC procedures, permit hierarchies, and compliance workflows. Kissflow's low-code platform allows you to configure approval routing, add site-specific requirements, and adapt workflows to your regulatory context—without programming. This is essential because downstream operations vary dramatically in process units, products, and regulatory jurisdictions.

The Kissflow mobile app allows inspectors and technicians to complete forms, take photos, and capture readings without connectivity. Data is stored locally on the device and automatically syncs when it return to network coverage. This is important for large refinery sites where cellular coverage is spotty, and critical for retail auditors visiting remote locations.

Simple workflows (shift handovers, incident reporting) deploy in 3-4 weeks. More complex implementations (integrated turnaround coordination with contractor management and permit tracking) typically take 6-10 weeks. Timeline depends on integration requirements with existing systems and workflow complexity. For operating refineries, phased deployment is recommended—start with one unit or one workflow, validate, then expand. Never rush deployment in 24/7 operations.

Based on our downstream customer deployments, typical ROI includes 45% reduction in turnaround delays, 50-60% improvement in contractor management efficiency, and 30-40% faster engineering change approvals. Our refinery customers report saving millions annually through optimized turnarounds, improved retail operations, and streamlined compliance processes.